The greenhouse effect is one of the biggest environmental problems facing the 21st century. Excessive emission of greenhouse gases is the main cause of the greenhouse effect. About 17% of the carbon dioxide in greenhouse gases comes from the combustion of internal combustion engines in cars and trucks.Therefore, reducing dependence on oil for transportation is a solution to avoid environmental problems.Material battery technology has attracted considerable attention as a potential alternative power generation technology, and has the advantages of zero emissions, high efficiency, and rapid response to load changes.Fuel cells are generally more efficient than their traditional power generation counterparts, such as gas turbines and reciprocating engines, with power generation efficiencies of over 50%.Combined with the existing environment and current situation, the increasing demand for power generation and the lack of large-scale central power stations developed in congested areas, fuel cells will quickly become the main device in the distributed power generation market.The greenhouse effect is one of the biggest environmental problems facing the 21st century. Excessive emission of greenhouse gases is the main cause of the greenhouse effect. About 17% of the carbon dioxide in greenhouse gases comes from the combustion of internal combustion engines in cars and trucks.Therefore, reducing dependence on oil for transportation is a solution to avoid environmental problems.Material battery technology has attracted considerable attention as a potential alternative power generation technology, and has the advantages of zero emissions, high efficiency, and rapid response to load changes.Fuel cells are generally more efficient than their traditional power generation counterparts, such as gas turbines and reciprocating engines, with power generation efficiencies of over 50%.Combined with the existing environment and current situation, the increasing demand for power generation and the lack of large-scale central power stations developed in congested areas, fuel cells will quickly become the main device in the distributed power generation market.

Fuel cells have the following advantages: high conversion rate; clean and quiet; easy installation; easy access to fuel.Fuel cells are usually divided according to the type of electrolyte they use, and can be divided into: proton exchange membrane fuel cells, phosphoric acid fuel cells, alkaline fuel cells, direct methanol fuel cells, molten carbonate fuel cells, solid oxide fuel cells, zinc Air fuel cell, photonic ceramic fuel cell.The temperatures they require also vary.

Commonly used base materials for fuel cell gas diffusion layers are:

carbon paper: Carbon paper is a functional paper with a certain fiber content. Its production process is to mix chopped carbon fiber and adhesive and obtain it through staining, molding, curing, carbonization, graphitization and other processes. It can be used for fuel cell gas diffusion. It is a layer of functional paper, and the graphitization treatment is to make the carbon paper have good electrical conductivity, thermal conductivity and thermal stability.Carbon paper is a fiber skeleton, so it has a porous structure and can be used as a material for gas diffusion layers. However, the overall strength of carbon paper is low and it is prone to deformation and breakage, which has become a research hotspot at this stage.

Carbon fiber cloth: Also known as carbon fiber woven cloth, carbon cloth, carbon fiber prepreg cloth, etc.Carbon fiber cloth has the characteristics of high strength, low density, thin thickness, etc. It also has high durability and is suitable for environments such as acid, alkali, salt and atmospheric corrosion.

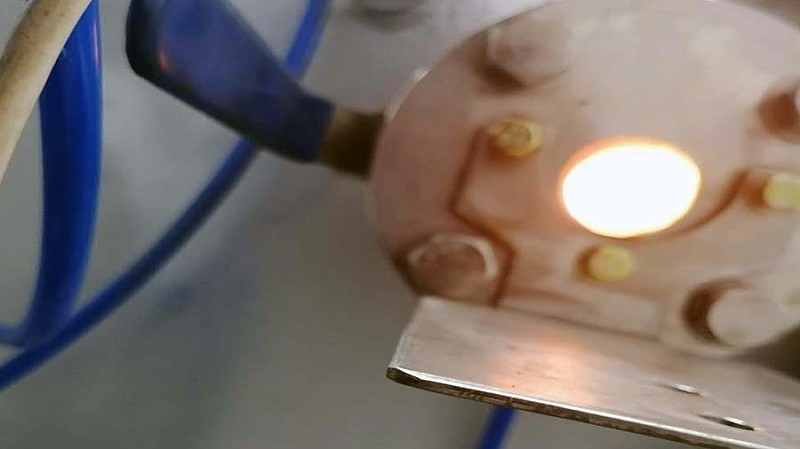

High-performance carbon paper has increasingly higher performance requirements for carbon paper and carbon cloth used in fuel cells. Among them, low-temperature carbonization, medium-temperature carbonization, high-temperature carbonization and ultra-high temperature graphitization are one of the key steps in modifying carbon paper. Our company In long-term cooperation with relevant domestic scientific research institutions and enterprises, we have developed an integrated gap experimental furnace and a large-scale production type suitable for high-temperature treatment of carbon paper carbonization, carbon paper graphitization, carbon paper modification, carbon cloth carbonization and graphitization. Carbon paper carbon cloth continuous furnace

The carbon paper and carbon cloth integrated experimental furnace for carbon fossil graphitization in fuel cells has the following characteristics

Square furnace, more space saving than conventional circular furnace, more suitable for stacking and placement of carbon paper, placement of carbon cloth stretching fixtures, and various placement schemes

Larger space, length 200mm x width 200mm x depth 300mm, fully meeting the current research needs of various specifications and types of carbon paper and carbon cloth

Integrated modular space layout, integrating all aspects including power supply system, water cooling system, furnace body, furnace door, insulation, various protections, etc. into a space of 4 meters in length, 3 meters in width, and 2.5 meters in height, occupying a more compact area. Installation only requires the installation of power supply, air intake, tap water, or external circulating cooling water, fully considering the characteristics of small laboratory space, limited entrance and exit doors, or the general layout of the laboratory on the second or higher floors.

Using the latest IGBT power supply, compared to conventional thyristor frequency modulation power supply, it has the characteristics of low sound, high power factor, and low harmonic interference. This has fully verified the harmonic interference of other experimental electrical equipment

The redesigned fully automatic furnace door is more user-friendly for scientific researchers and experimenters. When handling samples, there is no need to manually open the furnace door or operate the insulation cover, and the equipment is fully automatic with just one click.

It has a full range temperature measurement of room temperature -3200 degrees, with both thermocouple temperature measurement and dual color infrared temperature measurement. It has more accurate low temperature and higher high temperature, complementing each other. All low and high temperatures can be handled by one device.

Up to 20 heating process options, all of which are automatically controlled by computers, including vacuum displacement in the early stage, gas filling for heating, insulation, cooling, and more.