Purchasing hotline:08615273391550

上一张

下一张

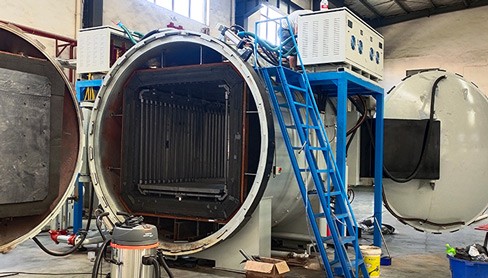

It can realize vacuum sintering, partial pressure sintering, micro positive pressure sintering and other processes of silicon carbide, carbon/carbon, transparent ceramics, carbon ceramics and other composite materials.

| internal effective volumemm | Square | 300X300X600 | 400X400X800 | 500X500X1200 | 600X600X1500 | 700X700X1600 | 900X900X2000 |

| round | φ200X300 | φ400X800 | φ500X1200 | φ600X1500 | φ700X1600 | φ900X2000 | |

| control method | Thyristor or IGBT control (customer specified) | ||||||

| heating method | Graphite resistance heating or medium frequency induction heating (customer specified) | ||||||

| Equipment structure | Horizontal or vertical (customer specified) | ||||||

| Furnace configuration | One power supply controls one or more furnaces (the best method based on customer process and material heat calculation) | ||||||

| Power supply | KW | 70 | 120 | 200 | 260 | 300 | 500 |

| Power output frequency | HZ | 4000 | 2500 | 1500 | 1000 | 1000 | 900 |

| Use high temperature | ℃ | 2400 | 2400 | 2400 | 2400 | 2400 | 2400 |

| Ultimate vacuum degree | pa | 20 | 20 | 20 | 20 | 20 | 20 |

| Furnace working environment | Vacuum or pre-evacuate and then introduce protective gas | ||||||

The pressureless sintering furnace can realize vacuum sintering, partial pressure sintering, micro positive pressure sintering and other processes of composite materials such as silicon carbide, carbon/carbon, transparent ceramics, carbon ceramics, etc. It is suitable for sintering products of different shapes and sizes, and is equipped with reliable The filtration and vacuum system handles the volatilization of sintering aids.

The imported high-precision temperature controller and double thermocouple are used to control the cooling rate strictly according to the process requirements, effectively avoiding product cracks and yield.

The pressureless sintering furnace adopts a special furnace structure and heater arrangement. The furnace temperature It has good uniformity and is suitable for the long-term sintering process of pressureless sintering.

The pressureless sintering furnace adopts advanced heat insulation structure and materials. The furnace has good heat insulation performance and less hea

The pressureless sintering furnace adopts touch screen operation and PLC centralized control, which is simple to operate and has high reliability.

The pressureless sintering furnace has over-temperature and over-pressure fault alarms, mechanical automatic pressure protection, action interlocking and other functions. The furnace body explosion-proof valve is exclusively designed to ensure high equipment safety.

The pressureless sintering furnace has functions such as remote operation, remote fault diagnosis and remote software upgrade.

Related Products

Related Products

The small atmosphere vacuum box-type high-temperature furnace is a new type of furnace newly develop...

Learn More

Vacuum medium frequency sintering furnace is a periodic operating electric furnace, which is widely ...

Learn More

High-temperature equipment that can perform firing and carbonization under high vacuum or atmosphere...

Learn More

High-temperature equipment that can perform firing and carbonization under high vacuum or atmosphere...

Learn More

It is mainly used for the medium and low temperature carbonization process of PI film, carbon/carbon...

Learn More