Purchasing hotline:08615273391550

上一张

下一张

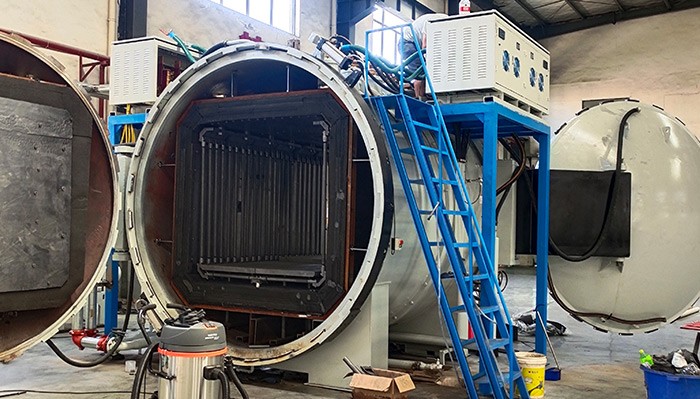

The small atmosphere vacuum box-type high-temperature furnace is a new type of furnace newly developed by our company. It has high temperature control accuracy of ≤0.1℃, good temperature uniformity of ±2℃, and the temperature can reach 2300℃.Small footprint and flexible turnover.Especially suitable for small batch production or laboratory use.

1. Model: YHGYL-THL45/45-50

2. Heating method: isostatic graphite resistance heating

3. Power supply control: low DC voltage, high current mode

4. Design power is 60KW, actual production power is not more than 50KW

5. Power supply: Three-phase five-wire system, three-phase 380V, frequency 50HZ

6. Design temperature: 2100℃, long-term common temperature is 2000℃;

7. Cooling method: natural cooling

8. Effective discharge space: width 450mmX height 450mm depth 500mm

9. Heating rate : When loading, the average heating rate below 1000℃ is 5℃/min, the average heating rate between 1000-1800℃ is 5℃/min, the average heating rate between 1800-2250℃ is 3℃/min

10. Temperature control accuracy: RT room temperature -2000℃ ≤±2℃

11. Power supply configuration form: integrated with the furnace body

12. Furnace form: horizontal front door discharging

13. Working gas content in the furnace: vacuum or Ar, N2, NH? and other gases (slight positive pressure), vacuum replacement;

14. Temperature uniformity: ≤±3℃ (evaluated after holding the temperature for 30 minutes);

15. Temperature measurement: Single-zone tungsten sleeve tungsten-rhenium thermocouple temperature measurement

16. Temperature control: Japan Shimaden FP23, PID intelligent temperature controller program control ( Temperature control accuracy: ±0.1℃) and manual control;

17. Protection method: PLC + touch screen + sound and light alarm

18. Vacuum system configuration: 2H-70 slide valve pump

19. Vacuum measurement: resistance + capacitance film vacuum gauge, measuring range 0-105pa

20. Pressure rise rate: vacuum to 5Pa, stop the pump for 30 minutes and start timing, pressure rise per hour ≤ 10P

21. Cold ultimate vacuum degree: ≤5Pa (in clean, cold, empty furnace state)

22. Empty furnace vacuum time ≤20min (empty furnace, room temperature, refer to GB/T10066.1-2004 for testing.)

23 . The maximum pressure in the furnace is 0.02Mpa

24. Explosion-proof valve trip pressure: 0.07Mpa

25. Cooling system: All circulating water pipes are well sealed and there is no leakage during use;

26. Electrical control: Siemens PLC + Delta 15-inch touch screen, key Parameters such as vacuum degree, temperature, and power can be queried in real time and historically, and can be exported through a USB flash drive, and a paperless recorder can be set up.

27. Key components are made of imported materials, such as temperature control instruments and thermometers.28. Opening method: manual

29. Material inlet and outlet method: equipped with a special inlet and outlet truck

30. Paint color: main body milky white, frame sky blue, base black

The maximum working temperature is 2300°C, and the common temperature is 2250°C.

Working atmosphere: air atmosphere, vacuum sintering or reducing atmosphere sintering (slight positive pressure)

Temperature measurement: thermocouple and far-infrared optical temperature measurement component form

Temperature control: program control and manual control; Temperature control accuracy: ±0.1℃

Related Products

Related Products

It can realize vacuum sintering, partial pressure sintering, micro positive pressure sintering and o...

Learn More

Vacuum medium frequency sintering furnace is a periodic operating electric furnace, which is widely ...

Learn More

High-temperature equipment that can perform firing and carbonization under high vacuum or atmosphere...

Learn More

High-temperature equipment that can perform firing and carbonization under high vacuum or atmosphere...

Learn More

It is mainly used for the medium and low temperature carbonization process of PI film, carbon/carbon...

Learn More