Purchasing hotline:08615273391550

上一张

下一张

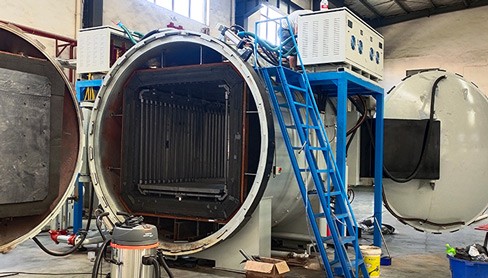

This high-temperature graphitization furnace is a new type of furnace redeveloped based on the original medium frequency high-temperature furnace and has been put on the market. It is specially used as a processing equipment for carbonization and graphitization of graphene/polyimide composite films to ensure accurate temperature control. , The equipment is stable, simple to operate, the power consumption per square meter is 15-25% lower than similar equipment on the market, and its strong insulation and anti-corrosion properties are well received by customers.

1. Maximum operating temperature: 3000℃, common temperature is 2500℃

2. Working atmosphere in the furnace: nitrogen or other inert gases, etc.

3. Temperature measurement: far-infrared optical temperature measurement, temperature measurement range 1000~3200℃ or 600~3100℃, Temperature measurement accuracy: 0.2~0.75%

4. Limit heating rate: room temperature -1500 degrees is 15℃/min, 1500-2500 is 10℃/min, 2500-3000 is 5℃/min

5. Furnace temperature uniformity: ≤± 2℃, (for equipment with an internal space diameter of Φ500mm and a height of 1000mm, measured at a constant temperature of 1750℃ for 60 minutes)

6. Temperature control: program control and manual control; temperature control accuracy: ±1℃

01

The equipment has a high degree of automation. All switch components and all operating parameters of the equipment are stored in the PLC database in digital form, and communication interfaces can be reserved to facilitate customer connection.

02

The ultra-high temperature furnace body within 3000℃ can meet the carbonization and graphitization of graphene/polyimide composite films.

03

Using a digital display intelligent temperature control system, the temperature measurement and temperature control process is fully automatically completed with high precision. The system can heat up according to a given heating curve, and can store twenty different process heating curves with a total of 400 segments.

04

The interior of the furnace body and all pipes are all insulated and subjected to high-strength anti-corrosion treatment to adapt to the volatile deposition characteristics produced during thermal cracking during the carbonization and graphitization of the graphene/polyimide composite film.

05

Adopts internal circulation pure water cooling system; digital flow monitoring system; furnace conversion adopts high-performance medium frequency contactor; comprehensive PLC water, electricity and gas automatic control and protection system

06

The unique induction coil uses five times of insulation treatment to completely solve the problem of induction coils or applications that require high-temperature insulation. It ensures that the coil can still maintain good insulation performance even if the corundum ages and cracks, and can effectively prevent coil ignition, current leakage and other phenomena.

Related Products

Related Products

The small atmosphere vacuum box-type high-temperature furnace is a new type of furnace newly develop...

Learn More

It can realize vacuum sintering, partial pressure sintering, micro positive pressure sintering and o...

Learn More

Vacuum medium frequency sintering furnace is a periodic operating electric furnace, which is widely ...

Learn More

High-temperature equipment that can perform firing and carbonization under high vacuum or atmosphere...

Learn More

High-temperature equipment that can perform firing and carbonization under high vacuum or atmosphere...

Learn More