Purchasing hotline:08615273391550

上一张

下一张

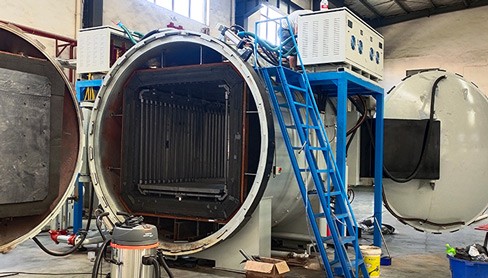

The horizontal high-temperature graphitization furnace produced by our company is mainly used for the sintering and graphitization of carbon materials, graphitization of PI films, graphitization of thermal conductive materials, sintering of carbon fiber ropes, sintering graphitization of carbon fiber filaments and other applications in carbon environments. Graphitized materials.Compared with the conventional vertical graphitization furnace, the horizontal graphitization furnace has the same working principle. It mainly has the advantages of convenient loading and unloading, convenient cleaning in the furnace, easier control of the operating status by workshop patrol personnel, and easy daily maintenance and replacement of consumable parts in the furnace. and other advantages, but the cost is slightly increased.

Compared with the inner string graphitization furnace and the Acheson graphitization furnace, the disadvantage is that the furnace capacity is small, but the temperature is uniform, the production cycle is short, the project environmental impact assessment is easy to achieve, and the graphitization furnace temperature measurement device can be installed in a timely manner. Under special circumstances, it can Realistic hydraulic pressurization and other advantages.

|

Product model specifications (Diameter x lengthmm) |

Φ400×1000 | Φ500×1000 | Φ600×1200 | Φ700×1600 | Φ900×1600 |

| Medium frequency power supply power Kw | 130 | 200 | 260 | 300 | 500 |

| Medium frequency power supply frequency Hz | 1500 | 1000 | 1000 | 1000 | 1000 |

| Maximum operating temperature℃ | 3000 | 3000 | 3000 | 3000 | 2850 |

| Ultimate vacuum degree Pa | 1.2×10-1 | 1.2×10-1 | 1.2×10-1 | 1.2×10-1 | 1.2×10-1 |

| Pressure rise rate Pa/h | 0.67 < | 0.67 | 0.67 | 0.67 | 0.67 |

| Temperature difference in constant temperature zone℃ | ±10 | ±10 | ±10 | ±10 | ±15 |

01

The equipment has a high degree of automation. All switch components and all operating parameters of the equipment are stored in the PLC database in digital form, and communication interfaces can be reserved to facilitate customer connection.

02

The ultra-high temperature furnace body is within 3000℃, which can meet the graphitization treatment of various carbon materials.

03

Using a digital display intelligent temperature control system, the temperature measurement and temperature control process is fully automatically completed with high precision. The system can heat up according to a given heating curve, and can store twenty different process heating curves with a total of 400 segments.

04

Completely solved the problem of ablation and sinking of the crucible inside the horizontal graphitization furnace. In actual production, 60 heats were produced and the sinking was only 5mm.

05

Adopts internal circulation pure water cooling system; digital flow monitoring system; furnace conversion adopts high-performance medium frequency contactor; comprehensive PLC water, electricity and gas automatic control and protection system.

06

The unique induction coil uses five times of insulation treatment to completely solve the problem of induction coils or applications that require high-temperature insulation. It ensures that the coil can still maintain good insulation performance even if the corundum ages and cracks, and can effectively prevent coil ignition, current leakage and other phenomena.

Related Products

Related Products

The small atmosphere vacuum box-type high-temperature furnace is a new type of furnace newly develop...

Learn More

It can realize vacuum sintering, partial pressure sintering, micro positive pressure sintering and o...

Learn More

Vacuum medium frequency sintering furnace is a periodic operating electric furnace, which is widely ...

Learn More

High-temperature equipment that can perform firing and carbonization under high vacuum or atmosphere...

Learn More

High-temperature equipment that can perform firing and carbonization under high vacuum or atmosphere...

Learn More